So, you think you may have a faulty fuel pump? Troubleshooting the problem is usually pretty straightforward. But occasionally, a tricky diagnosis will have you pulling out your hair and throwing wrenches. That’s why it’s helpful to have a few extra diagnostic tricks up your sleeve.

Before beginning, you’ll want to have the vehicle’s repair information handy. Manuals, such as those from Chilton, are good but an ALLDATA subscription is even better. ALLDATA has single-vehicle subscriptions for DIYers that provide detailed factory repair information.

Also, keep in mind, other issues can mimic a faulty fuel pump. You’ll want to perform a thorough diagnosis to ensure the pump is the problem before replacing it. And consult the previous article in this series regarding fuel pump symptoms to understand how both continuous and returnless fuel systems work.

Note: The following is for informational purposes only. Consult the factory information for repair instructions and recommended safety procedures.

The first step is to verify the problem is fuel related. Then, you can do additional testing to find out if the pump is to blame.

If the engine won’t start:

- Listen for the fuel pump: Put your ear near the fuel tank and have an assistant turn the ignition key to the “on” position. The fuel pump should make an audible noise. If it doesn’t, you’ll need to make sure the engine controller is awake. You’ve probably already connected your scan tool and if the PCM will talk to the scan tool, you know the PCM is awake. If it won’t talk, find out why.

- Next, you need to know if the vehicle has a fuel pump control module between the fuel pump relay and the pump. If it does, the following test procedures won’t work. If the relay directly powers the pump, you can try swapping out the relay, but if that doesn’t take care of the problem, use this procedure:

Find the Fuel Pump Relay: Once you locate the fuel pump relay and the related fuse, check the fuel pump fuse, and if it’s not blown, feel the relay while somebody switches the key on without spinning the engine. You should feel the fuel pump relay click and then click again 2 seconds later. But just because a relay clicks, it doesn’t mean the relay is delivering power to the fuel pump. If it clicks, a mechanic will remove the relay and use a test light to check the terminals as follows:

With the key on and the test light clip connected to the negative battery terminal, you should find two hot terminals. Mark those two terminals. One is the coil feed and the other is the power the relay delivers to the pump.

Move the test light clip to the positive post. One of the other two terminals should be grounded – if one of them is showing a ground, that ground is coming through the pump windings. That means the pump circuit is complete.

If neither of the two non-hot terminals are grounded, the fuel pump windings are open or there is an open circuit between the relay and the fuel pump. Keep the test light there and have somebody kick the gas tank or hit it with a soft rubber hammer. If the light comes on when the tank is hit or kicked, the fuel pump will need to be replaced because the brushes are worn out.

If one of the non-hot terminals is grounded, check the fourth terminal for a ground while the key is cycled off and then on – you should see a 2-second ground being delivered from the PCM to the relay. - Use starter fluid: Be warned: this procedure can cause personal injury, as well as damage to your engine. Try it at your own risk with the proper safety equipment, such as a fire extinguisher, on hand. Definitely wear your safety glasses. Do not use starter fluid on a diesel engine.

If you decide to attempt the test, try to start the vehicle by removing the air intake and spraying starter fluid into the throttle body. Have an assistant crank the engine while you spray – if it starts and runs momentarily, the problem is fuel-related and may indicate a bad pump. You’ll want to check fuel pressure as your next step.

If the engine won’t start OR it exhibits performance problems:

- Check for diagnostic trouble codes (DTCs) with a scanner or code reader: In some cases, a faulty pump may set DTCs in your car’s computer. And again, if there is a datastream display showing fuel pressure, see what the pressure is and notice what it does under heavy acceleration (get an assistant to watch the tool while you drive or vice versa.

- Any DTCs may either be directly related to the fuel pump or make reference to an air/fuel ratio problem. A scan tool or a simple code reader can be used to retrieve the information. Many auto parts stores will pull codes for free but be careful not to let them talk you into buying parts you don’t need; there’s more to finding a problem than simply pulling a trouble code. Plus, there are inexpensive code reading tools and apps for your smartphone. Even if there are codes, you’ll want to check fuel pressure as your next step.

- Check fuel trim with a scan tool: This test only applies if the engine is running. All scan tools (not code readers; there’s a difference) will display a data parameter called short term fuel trim (STFT). As a general rule of thumb, fuel trim readings should be between -10 and 10, though some vehicles are different.

If fuel trim is above 10, that means the engine is running lean and the fuel pump may not be delivering. Keep in mind, however, other factors, such as vacuum leaks, can cause a lead running condition as well. So, you’ll want to check fuel pressure as your next step.

Check fuel pressure and/or volume

Checking fuel pressure and/or volume will tell you whether or not enough fuel is making it from the tank to the engine. But that doesn’t necessarily mean the pump is bad. It’s wise to do further testing to rule out fuel pump circuit issues and other problems, such as a clogged fuel filter or bad pressure regulator, that could limit the fuel supply.

Caution: Before hooking up a fuel pressure gauge, be sure to relieve fuel system pressure as outlined in your repair manual. Have your safety glasses on and a fire extinguisher nearby.

- Check fuel pressure: Mechanical fuel pressure gauges are inexpensive and readily available.

Performing a static fuel pressure test is pretty straightforward. Simply connect the gauge as outlined in your repair manual. Most modern vehicles have a handy test port located on the fuel rail.

Next, turn the ignition to the on position (key on, engine off), note the reading on the gauge and compare it to the specification listed in your repair manual. If the reading varies significantly from spec, you may be dealing with a bad fuel pump.

Also, when performing a static test, you’ll want to note whether the pressure holds. The factory repair information will tell you how long (usually several minutes) fuel pressure should hold once the pump is turned off. If pressure bleeds off too fast, there is a fuel-related problem such as a bad pump check valve or faulty regulator.

Those looking to perform a more in-depth fuel pressure assessment may choose to check fuel pressure at idle or under load. Also, continuous fuel systems can be checked for “dead head” pressure (pressure with the return line pinched off). But that test does not work on newer returnless systems that have the regulator in the tank.

- Check fuel volume: A pump may produce adequate pressure yet not create enough volume. And that’s where a fuel pump volume test comes in handy. In many cases, you can use a fuel pressure gauge to measure volume as well.

Start by connecting the gauge and placing the bleed end of its hose into a clean container. Without starting the engine, activate the pump for 15 seconds while you hold down the relief valve on the tool. Typically, the pump should deliver about a pint of fuel during that time. Consult the repair information for the exact procedure and specifications for your vehicle.

Part 2: Before condemning the pump…

So, you’ve verified a lack of fuel pressure and/or volume and now, you think you can condemn the pump. But wait – not so fast. In many cases, you’ll want to check the following beforehand:

- Check the fuel pump electrical circuit (see earlier instructions): In most older continuous-style fuel systems, the engine control module (ECM) controls the fuel pump via a relay. You’ll want to check that relay before condemning the fuel pump.

In many newer, returnless fuel systems, the fuel pump control module (FPCM) directly controls the fuel pump. The device uses information from sensors, such as the fuel pressure sensor and fuel temperature sensor, to determine control of the pump’s ground circuit and vary the pump’s speed. It’s a good idea to make sure everything within the control system is working properly before blaming the pump.

With both continuous and returnless systems, you’ll also want to check the integrity of the wiring in the pump circuit before jumping to conclusions. A digital multimeter (DMM) can be used to check the circuit for continuity, power and ground, as well as any unwanted excessive resistance.

- Check the fuel pressure regulator: Returnless fuel systems do not have an external pressure regulator. Typically, the fuel pressure regulator will fail so that there is too much fuel pressure rather than not enough, but on many modern systems, the regulator is part of the pump assembly, so make sure you know whether that applies to yours.

- Check the fuel filter: Continuous fuel systems have an external filter that’s relatively easy to install. Rather than attempting to test the filter, it’s usually easier to just install a new one and see if that helps. Remember to relieve fuel system pressure before replacing the filter. Have your safety glasses on and a fire extinguisher nearby.

Part 3: Advanced tests

There are a couple of advanced tests available for those who have the interest – and the money – to try them out.

Measure current draw with an oscilloscope

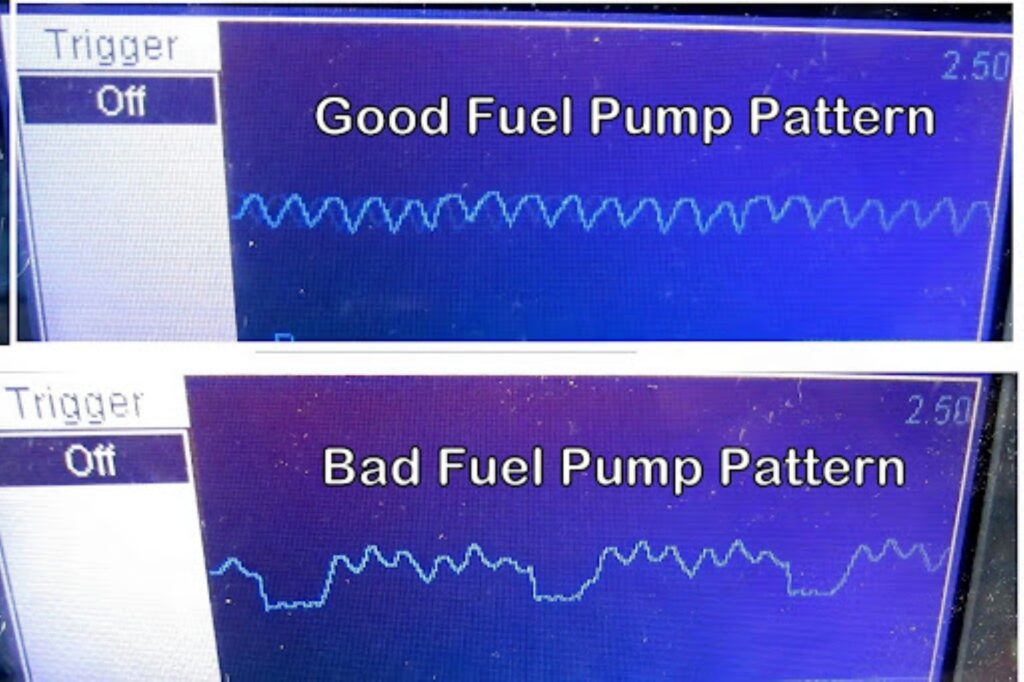

One of the best ways to test a fuel pump is with an oscilloscope and low amp clamp probe. Connecting the probe to the pump’s power wire provides a waveform pattern that, if you know what you’re looking for, exposes internal pump problems. Generally, a good pump should produce a pattern of even “humps” if it’s working properly. If the pump is bad, the humps will be jagged and uneven.

A missing wave in the pattern usually indicates a burned-out winding or an open circuit. Meanwhile, waves that vary in shape and size point to worn brushes and commutators.

Before doing a fuel pump test using an oscilloscope, familiarize yourself with your vehicle’s connections and wirings. You’ll have access to the fuel pump relay to connect the digital oscilloscope.

What is an Oscilloscope?

An oscilloscope tracks how voltage signals change over time, displaying them on a screen. It’s like a digital graphing tool that shows different waveforms.

Aside from diagnosing automotive issues using voltage signals, an oscilloscope is also used in various applications in areas like electronics, telecommunications, and engineering.

Use a professional-grade scan tool

Some high-end scan tools allow remote fuel pump testing. By pushing a couple of buttons on the tool, you can activate the pump to see if it runs.

How Do You Know When the Fuel Pump Is Bad?

A faulty fuel pump that needs replacing can act up in different ways, but some of the most common symptoms include a sputtering engine and a strange whining sound from the fuel tank.

When driving up an incline, you’ll also notice your vehicle losing power. The fuel pump might move a little bit of gas, but not enough to keep up with any additional stress. Because of this, your car is also likely to struggle when you put heavy cargo in the trunk.

If the fuel pump is completely dead, the engine won’t run, leaving you with a vehicle that won’t start.

How Does a Car Act When the Fuel Pump Is Going Out?

When the fuel pump fails to send enough fuel to your engine, your engine won’t be able to power your car. Your vehicle is likely to sputter or suddenly die as you drive.

In some cases, your car can also refuse to start. It might crank when you turn the key in the ignition, but you’ll have to try multiple times just to get it to start.

Will a Fuel Pump Still Run if It’s Bad?

While a fuel pump might still run even if it’s damaged, it’s likely to cause the engine to run poorly. It’s only a matter of time before it fails entirely, so it’s best to avoid driving until you replace it.

How to Get a Replacement Fuel Pump

Driving around with a faulty fuel pump is a bad idea. It can cause poor fuel efficiency, stalling, and engine damage. If you don’t want to pay a bigger repair bill, then you should visit a mechanic or replace your bad fuel pump as soon as possible. Luckily, getting a new fuel pump is fast and easy with CarParts.com.

CarParts.com offers a wide selection of fuel pumps that are all sourced from the most trusted manufacturers in the industry. For easier browsing, make sure to use our vehicle and search filters, so you can see all the available parts that are compatible with your ride. You’ll be pleased to know that CarParts.com also guarantees fast shipping. Thanks to our strategically located warehouses around the US, you can expect your new fuel pump to arrive in as fast as two business days. Just be sure to order by 12 PM ET.

Don’t wait for your faulty fuel pump to damage other parts of your engine before replacing it. Check out our catalog of high-quality fuel pumps at CarParts.com and order today!

Products Mentioned in this Guide

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.

Fuel Pump

Fuel Pump

Fuel Tank

Fuel Tank

Fuel Filter

Fuel Filter

Fuel Pressure Regulator

Fuel Pressure Regulator