Rotors don’t take fancy equipment to diagnose. Most professionals test-drive the vehicle to see how the brakes feel. Then they perform a visual inspection of the rotors and, if necessary, measure the rotors as well. That’s it.

Front Brake Disc Inspection Methods

Rotors are simple, disc-shaped slabs of metal. As such, they’re usually pretty easy to diagnose.

Note: The following are general guidelines for educational and entertainment purposes only. Consult your vehicle’s factory information for specific repair instructions and recommended safety procedures.

1. Go by Pedal Feel

Pulsation or vibration while braking is almost always caused by warped rotors. There are other possibilities, such as a bad wheel bearing, but rotors are to blame most of the time. So, if your brake pedal pulsates while braking, you might want to just wing it and throw on a new set of front pads and rotors.

2. Visual Inspection

Take a look at your rotors: If they have deep scoring, extreme heat discoloration, hard spots, or cracks, it’s time for a new pair.

3. Take Measurements

If you want to be sure your rotors are worn, there are several measurements you can take. You’ll need a few special tools, such as a brake rotor micrometer and a dial indicator, to get the job done. Many professionals only take the time to measure thickness, but if you’re feeling ambitious, you can check all three measurements.

Obviously, you’ll need to raise and support the vehicle safely, then remove the wheel/tire assembly to perform these inspections. And don’t forget to put on your safety glasses. After you get the vehicle prepared, here’s what you can check:

- Minimum Thickness: All rotors have a minimum thickness specification supplied by the vehicle manufacturer. The measurement is often stamped into the front of the rotor, but it can be found in the vehicle repair information as well.

Checking for minimum thickness is easy. Simply use a brake micrometer in the middle of the rotor friction surface (where the pad makes contact). Note the reading: If it’s below the manufacturer’s specification, the rotor should be discarded.

- Runout: Next, you’ll want to check rotor runout. Runout, which is the side-to-side movement of the rotor as it turns, is measured with a dial indicator. To take this measurement:

- Remove the caliper mounting bolts. Do NOT unbolt the brake hose going to the caliper. You’ll let air into the hydraulic system if you do.

- Free the caliper by pulling it up and away from the rotor. If the caliper is stubborn, you may need to use a large screwdriver or pry bar to help free it.

- Use either a zip tie or a bungee cord to secure the caliper to the steering knuckle or another sturdy suspension component. Do not allow the caliper to dangle from the brake hose—damage may result.

- Remove the brake pads from the caliper mounting bracket (floating calipers only).

- Secure the rotor to the hub with the lug nuts.

- Attach the clamp end of the dial indicator to a sturdy, fixed location, such as the steering knuckle or caliper mounting bracket.

- Place the pointed end of the tool at the center of the rotor’s surface (where the pad would ride) and set the dial to zero.

- Turn the rotor by hand while keeping the tool perpendicular to the rotor surface.

Note the reading on the dial indicator; as a rule of thumb, runout should be less than .002 inch. It’s a good idea, however, to compare your reading to the manufacturer’s specification to be certain. If runout exceeds specification, the rotor should be resurfaced (if possible) or replaced (recommended).

- Thickness Variation (a.k.a. Parallelism): The final thing to check is thickness variation, which, as the name implies, checks the difference in width around the circumference of the rotor. Keep in mind: This measurement is difficult to take and often produces false readings.

If you decide to give it a try, measure the rotor thickness in at least eight different places [2] around the rotor. Then subtract the thinnest measurement from the thickest—that is your reading. Compare your reading to the manufacturer’s specification to see if your rotor should be resurfaced (if possible) or replaced (recommended).

If you find the rotors are worn beyond specification, you’ll want to service them right away. On the other hand, if the rotors look good, you can put everything back together. Be sure to torque both the caliper mounting bolts (if removed) and the wheel lug nuts to the manufacturer’s specifications.

Caution: Once everything is reassembled and the car is back on the ground, pump the brakes several times to ensure they feel firm. DO NOT drive the car until the brakes feel solid.

Here’s a tutorial video in case you need to replace your front brakes:

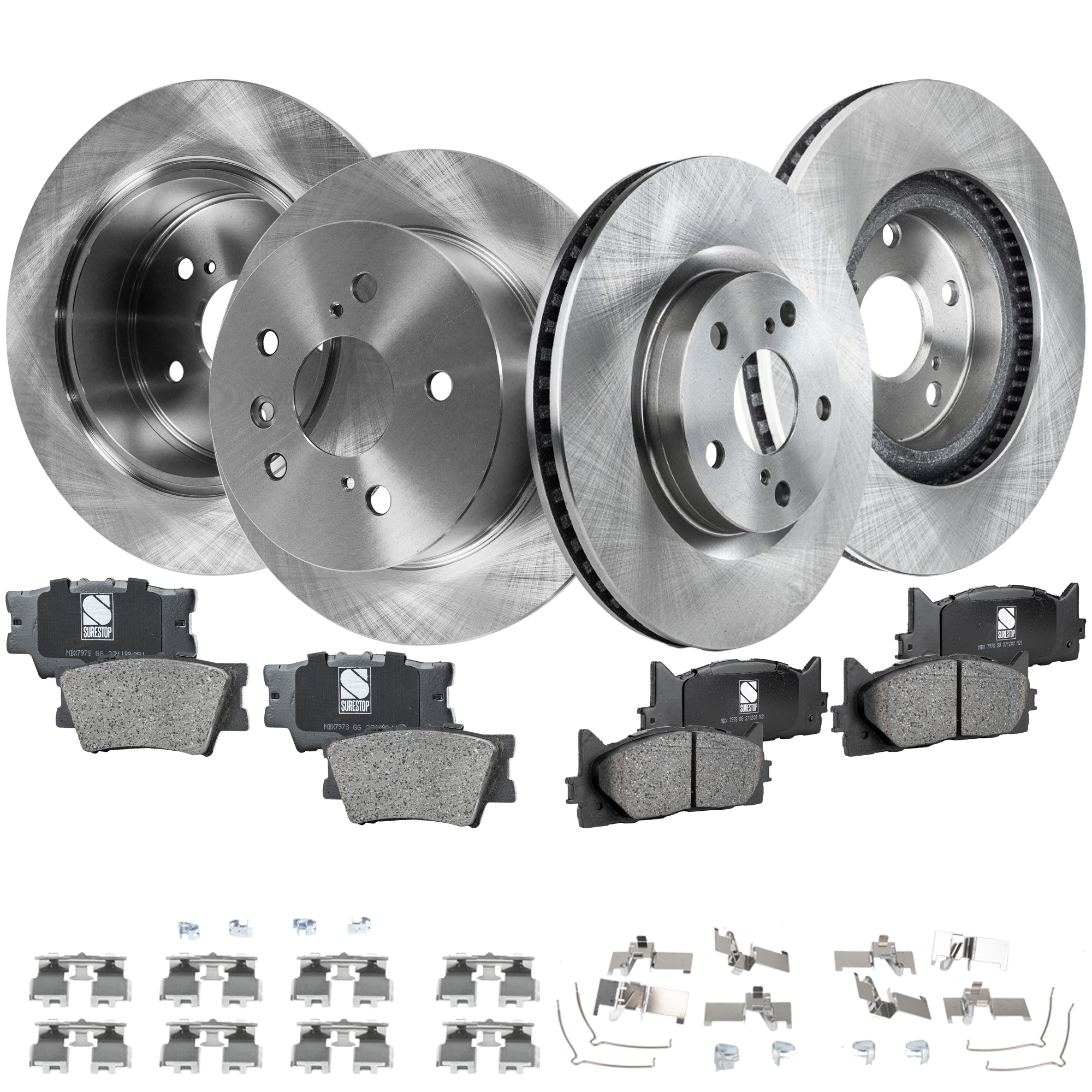

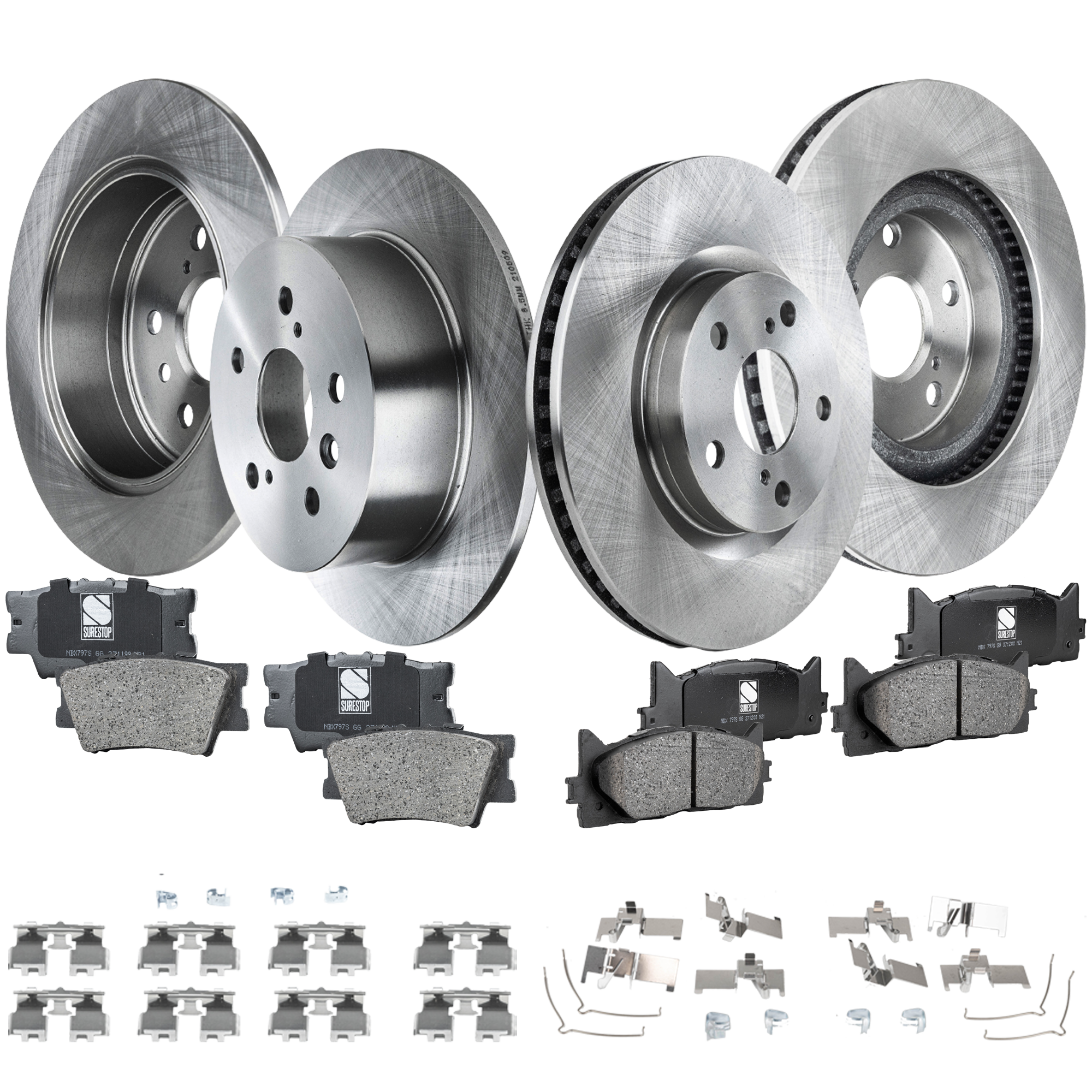

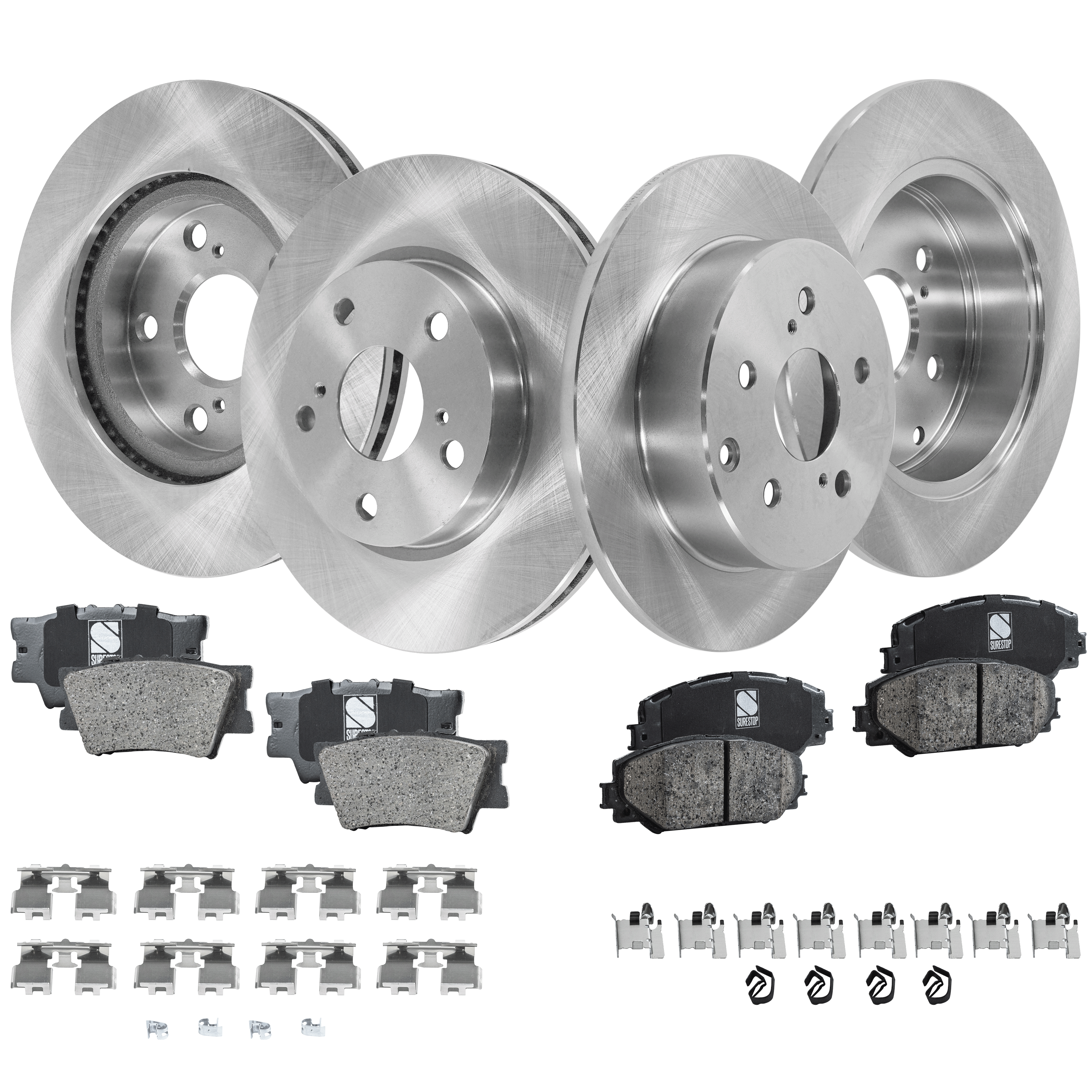

How to Get Replacement Brake Discs for Your Vehicle

You should never, ever drive with worn or damaged brake discs. Faulty brake discs can cause your brakes to overheat and become less effective. They negatively affect your brake system’s performance, increasing your risk of getting into a collision. For your own safety, it’s best to replace your brake discs as soon as possible. Luckily, getting brand-new brake discs is fast and easy with CarParts.com.

CarParts.com offers a wide selection of brake discs that are sourced from only the most trusted manufacturers in the industry. Make sure to use our vehicle selector and search filters, so you can easily browse through our catalog. Just enter your vehicle’s correct details, and you’ll see all the available parts that are compatible with your ride. If you’re itching to get back on the road, you’ll be pleased to know that CarParts.com also offers fast shipping. Order by 12 PM ET, and you can expect your new brake discs to arrive in as fast as two business days.

Don’t wait until your entire brake system fails before replacing your faulty brake discs. Check out our catalog of high-quality brake discs at CarParts.com and get yours today!

Shop this Project

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.