A synchromesh gearbox is a type of manual transmission that provides several benefits compared to a non-synchromesh gearbox. In this article, you’ll learn how a synchromesh gearbox works, how it differs from a non-synchromesh gearbox, and the benefits it offers.

What Is a Synchromesh?

A synchromesh transmission (also known as a synchronized transmission) system makes shifting smoother by providing a clutch between the gears. The functioning components of a synchromesh are also called synchronizers, which rest on the output shaft between gears. The main component of a synchromesh is a brass ring called the synchronizer ring. It acts like the clutch between the appropriate gear and the output shaft. It’s able to increase or decrease the appropriate gear’s relative speed so that the two gears can mesh perfectly.

How Does a Synchromesh Work In a Gearbox?

A synchromesh system makes a gear shift smoother by refining the process of meshing two gears together.

First, a part called a gear hub is attached to the output shaft that leads to the wheels. A part called a shift sleeve can freely slide over the gear hub and mesh with the appropriate adjacent gear. When this happens, the hub and the gear will spin together as a unit, and the wheels will spin based on the gear ratio of the selected gear. However, since the gear hub and the appropriate gear are spinning at different speeds, they need help from the synchronizers. The shift sleeve needs to mesh with the appropriate gear in a fluid manner to avoid vibration, noise, and damage.

A shift sleeve is responsible for managing two numbered gears. So, for example, one shift sleeve is responsible for sliding back and forth between the first and second gear, while another shift sleeve is responsible for sliding back and forth between the third and fourth gear, and so on.

A part called the synchronizer ring is sandwiched between the shift sleeve and another component called a synchronizer cone. The synchronizer cone is located alongside the appropriate gear.

When the driver selects a gear by moving the gear lever, the shift sleeve will push the synchronizer ring into the synchronizer cone. The synchronizer ring will then rub against the synchronizer cone like a clutch, increasing or decreasing the synchronizer cone’s speed depending on whether the driver is shifting up or shifting down.

The synchronizer ring and synchronizer cone have gears that align when they are synchronized. These gears will guide the shift sleeve into the appropriate gear.

What Is the Difference Between a Non-Synchromesh and Synchromesh Gearbox?

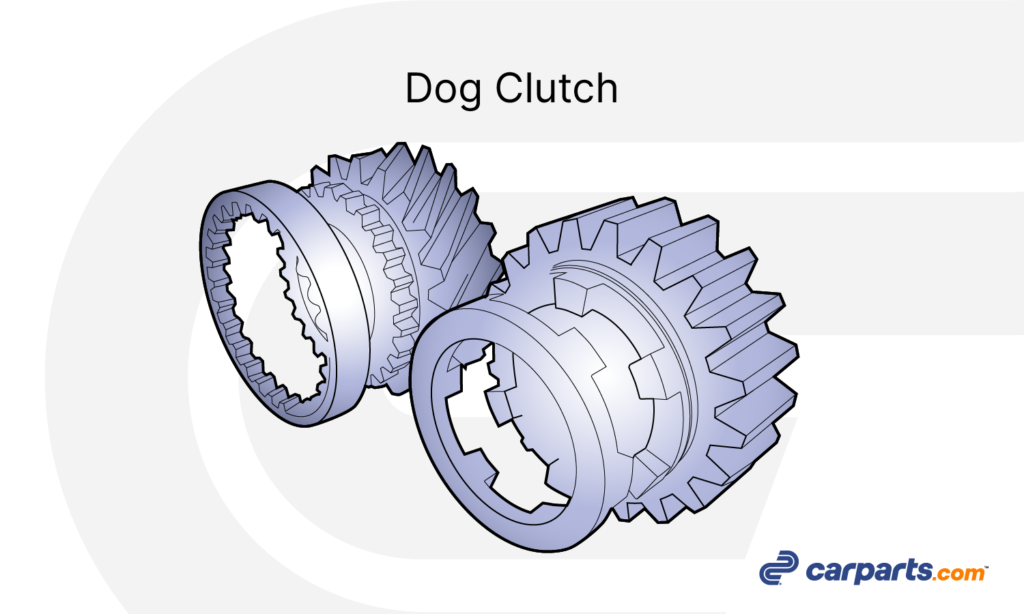

Non-synchromesh and synchromesh gearboxes are very similar. However, non-synchromesh gearboxes (sometimes called dog boxes in automotive applications) lack the refinement of a synchromesh gearbox. Instead of using a synchronizer ring and synchronizer cone to combine the shift sleeve and the appropriate gear, non-synchromesh gearboxes have a dog clutch. These dog clutches are essentially two opposing gears with large, squared teeth. However, one side has smaller teeth, so the two opposing gears don’t need to align perfectly to mesh together.

Unlike synchromesh gearboxes, dog clutches aren’t intended to rub and create friction. Dog clutches are meant to join the two gears by simply disrupting the momentum of the other gear.

Typically, non-synchromesh transmissions are found in race applications and motorcycles. On the other hand, synchromesh transmissions are what you’ll find in regular production cars.

What Are the Advantages of a Synchromesh Gearbox?

A synchromesh gearbox can shift gears more smoothly and generate less noise and vibration. You also don’t need to rev match or double clutch to shift gears smoothly. Instead, the synchronizer assemblies slow down or speed up the gear and shaft so that both are rotating at the same speed and can be locked together without clashing.

Where to Get New Synchromesh Transmission Parts

Avoid driving your vehicle until you get your transmission fixed. Transmission issues can cause your gears to slip or fail to engage, which puts you at greater risk of getting into an accident. For your own safety, you should replace defective parts as soon as possible. Luckily, getting new parts for your synchromesh gearbox is fast and easy with CarParts.com.

CarParts.com offers a wide selection of synchronizers, synchronizer rings, and other parts for your vehicle’s synchromesh transmission. With the help of our vehicle selector and search filters, you can easily browse through available parts that are compatible with your ride. Just be sure to input your vehicle’s correct year, make, and model. CarParts.com also guarantees fast shipping, so you don’t have to wait too long before you can get back on the road. Order by 12 p.m. ET, and you can expect your chosen component to arrive in as fast as two business days.

Don’t wait until your transmission system breaks down before replacing defective parts. Check out our selection of high-quality synchronizers, synchronizer rings, and other synchromesh transmission parts at CarParts.com and order one today!

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.