CAPA, or the Certified Automotive Parts Association, is a non-profit certification organization that establishes standards and specifications for replacement auto parts. When a product is CAPA-certified, it means that the product and its manufacturer have undergone inspection and testing, and that CAPA guarantees that the part meets their quality standards.

In other words, CAPA-certified parts are generally of a higher caliber than uncertified parts, which means they’re more reliable and can be trusted to get the job done.

But how can you tell if a part is CAPA-certified? How exactly does a part become certified in the first place, and what measures are taken to ensure each product lives up to quality standards?

How Can You Tell if Something is CAPA Certified?

The quickest way to tell if a product is CAPA-certified is to look for a distinctive yellow and blue seal. The seal always has a unique numerical code and barcode. The exact location of the seal depends on the part, but it should be someplace immediately obvious and easy to spot.

Is There Proof Against Fraud?

If a seal is all it takes to tell if something is CAPA-certified, then what’s stopping someone from swapping or forging it?

There are two protective measures CAPA takes to prevent fraud. The first is self-destructing seals. When a CAPA seal is attached to a certified product, it will self-destruct if any attempt is made to tamper with or remove it. This means seals cannot be transferred from part to part.

The second protective measure is the CAPA seal search page. You can verify the seal number through their website. All you have to do is type in the number indicated on the seal and click the “search” button. You should then be taken to a product page that corresponds to the seal number.

CAPA Certification: How It’s Done

There are two major steps when it comes to CAPA certification: manufacturer facility approval and vehicle test fit.

Manufacturer Facility Approval

The manufacturer must pass a detailed review and inspection of its factory and manufacturing process to prove that their products are up to par.

An independent testing laboratory will then validate whether or not the factory meets CAPA’s quality standards. This evaluation process will determine whether or not they can submit products for individual testing.

Vehicle Test Fit

After a manufacturer has been approved, they can submit individual parts for certification. Specific properties of each component are tested to ensure they meet CAPA’s standards. These include fit, finish, paint adhesion, coating performance, weld integrity, adhesive performance, and corrosion.

If the parts provided comply with CAPA’s quality standard requirements, the manufacturer is allowed to apply a CAPA Quality Seal, completing the certification process.

What Happens After Certification?

CAPA will continue to monitor manufacturing facilities and the products they make even after certification has been granted. This is done through regular random inspections to verify that CAPA quality standards are still being maintained post-certification.

Manufacturing facilities and products that fail to maintain these standards are subject to decertification.

Which Parts Typically Undergo CAPA Certification?

Because CAPA can certify aftermarket parts, the selection of components they can inspect varies greatly. This includes, but is not limited to, parts like ADAS sensors, bumper covers, bumpers, exterior cameras, headlights, mirrors, and replica wheels.

ADAS Sensors

Advanced driver-assistance systems (ADAS) sensors use ultrasonic sound waves to detect unseen objects around the vehicle, alerting the driver to avoid low-speed collisions. These sensors can typically be found in the front or rear of the vehicle.

What’s Tested: Function and performance, ingress protection, climate protection, voltage, vibrations, fit, dimensions, appearance, and materials used in the manufacturing process.

Bumper Covers

Also known as the front fascia, bumper covers are the frontmost part of the vehicle and are commonly mistaken for bumpers. This part serves as the “face” of the bumper, protecting it and giving it more aesthetic appeal.

What’s Tested: Adhesive, chemical and composition analysis, coatings, dimensions, electromagnetic compatibility, fasteners and hardware, primer, thermal properties, ultrasonic welds, vehicle test fit, and marks and labels.

Bumpers

The bumper is a durable metal component designed to absorb impact in the event of a collision, and it can be found at the front of the vehicle. Both metal and plastic parts are tested by CAPA before a bumper can be granted certification.

What’s Tested: Chemical analysis, dimensions, electrodeposition primer, fasteners and hitches, dynamic impact tests, mechanical properties, safety and handling, vehicle test fit, welds, and thermal properties.

Exterior Cameras

Many modern vehicles are equipped with exterior rearview cameras. This component is responsible for helping drivers see what’s behind their vehicle, reducing the risk of causing collision accidents by backing up.

What’s Tested: Image quality, ingress protection, electrical shock, mechanical shock, electromagnetic compatibility, material, and vehicle test fit.

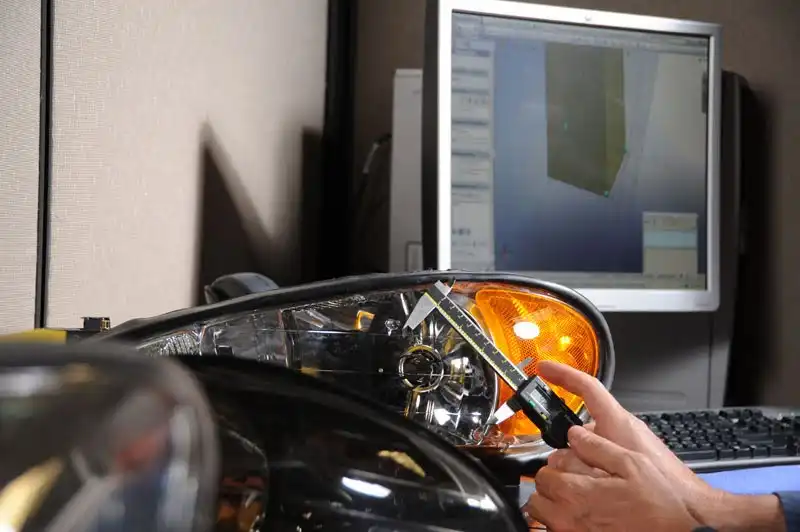

Headlights

Headlights are the lights installed in front of the vehicle. They improve visibility by illuminating the road in the dark, making it easier for drivers to see while making the vehicle more visible on the road.

What’s Tested: Plastic materials, performance, vehicle test fit, design file review, and part identification.

Mirrors

Car mirrors are external and are often installed on car doors, specifically the A-pillars. They help drivers see what’s behind them or along the sides of their vehicle.

What’s Tested: Reflectance, image stability, chemical analysis, adhesion, mirror thickness, dimensions, markings, and vehicle test fit.

Replica Wheels

Replica wheels are aftermarket wheels specifically designed to look and perform identically to OEM wheels.

What’s Tested: Performance, markings, chemical analysis, mechanical properties, fasteners and hardware, metallic coatings, painted coatings, dimensions, and appearance.

CAPA vs OEM: What’s the Difference?

You’ve likely seen the term OEM used to describe auto parts on the market before, but how exactly do they differ from ones that have CAPA certification?

CAPA-certified products are parts that have been recognized by CAPA for being reliable and high-quality, making them safe to use and install on your vehicle, provided they’re compatible. This means that all CAPA-certified products are aftermarket parts.

On the other hand, OEM parts, or Original Equipment Manufacturer parts, refer to components made by the automaker’s official parts manufacturers. Both the quality and the fit of OEM parts are guaranteed. These products are made in the same facilities as stock parts, guaranteeing maximum compatibility.

Is OEM Better than CAPA?

OEM parts are an excellent alternative to CAPA parts because they’re guaranteed to work with the vehicles they’re designed for. This makes them excellent replacements because they’re manufactured using the same technology and materials as stock parts.

However, this doesn’t mean that OEM parts are strictly better than CAPA parts.

The tradeoff is that OEM parts often cost more and, for certain makes and models, access can be limited. If OEM parts are difficult to obtain, CAPA-certified parts are an accessible and budget-friendly option you should consider.

Are Uncertified Parts Safe to Use?

If CAPA-certified products meet high quality standards, does this mean that uncertified products are generally of poorer quality? It depends.

Not all auto parts are created equal. Some will always be safer to use than others, and there are no easy ways to tell. Whether they’re CAPA-certified or not, certain products might have an edge over others in terms of quality, compatibility with other vehicles, and overall longevity.

Because of this, using uncertified parts will always be a gamble.

Since it’s difficult to tell if such parts are safe to use, it’s strongly recommended to do one of two things: spend the extra money to guarantee quality with CAPA-certified products, or do extensive research to ensure that the uncertified part you want is a good investment.

Will Using a CAPA-Certified Part Void a New Car’s Warranty?

No, using CAPA-certified parts will not void a new car’s warranty. CAPA parts may come with manufacturer warranties of their own.

It’s also worth mentioning that the Magnuson-Moss Warranty Act of 1975 makes it illegal to claim or imply that using a part made by anyone other than the original equipment manufacturer will void a warranty.

Are CAPA-Certified Parts Worth the Extra Cost?

More often than not, it’s a good idea to buy CAPA-certified products, even if they are a little costly. This is because you get what you pay for when it comes to auto parts.

CAPA-certified components are almost always more expensive than uncertified ones, and for good reason. Certification guarantees that the products work, are built to last, and can do their jobs without complications.

High-quality auto parts generally cost more because they’ve been tried and tested. You’ll be paying for the guarantee that the parts you purchase are up to par. Whether or not they’re worth the extra cost, however, depends on the parts you want to buy and how much you intend to buy them for.

Getting Your Hands on CAPA-Certified Auto Parts

If you don’t know where to look, ordering parts and products certified by CAPA can be difficult. Fortunately, CarParts.com is here to help.

To get started, visit our website and type “CAPA Certified” in the search bar. Once that’s done, hit the Enter key or press the golden button depicting a magnifying glass, and you’ll be free to browse our collection of CAPA-certified auto parts.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.