A failed head gasket is one of the most expensive non-engine-swap repairs you can face, and most of the bill isn’t the gasket—it’s the hours of disassembly, cleaning, measurement, and reassembly required to do the job correctly. When you approve a quote, you’re paying for precision machine work and careful sequencing, because shortcuts are what turn a repair into a repeat failure.

Before you spend thousands, it helps to understand how shops build the estimate, why prices vary wildly by vehicle, and what you can do to control the damage. If you already know the symptoms (overheating, white exhaust, milky oil), jump straight to the first section below for current price bands backed by real-world averages and labor-time realities.

How Much Does a Head Gasket Repair Cost?

Most drivers see quotes land between about $2,400 and $3,200 nationally for a typical modern passenger car, with labor making up roughly two-thirds of the total. That average aligns with large repair databases that track real invoices. On bigger or more complex engines—or when machine work and “while you’re in there” parts stack up—the out-the-door price can reach $4,000 to $6,000.

Why the spread? Time. A by-the-book head gasket job commonly consumes 8–12+ labor hours before any machine shop work; certain engines run longer. Add head milling, valve service, or broken fasteners, and you’re comfortably into the higher bands.

What the Estimate Should Include

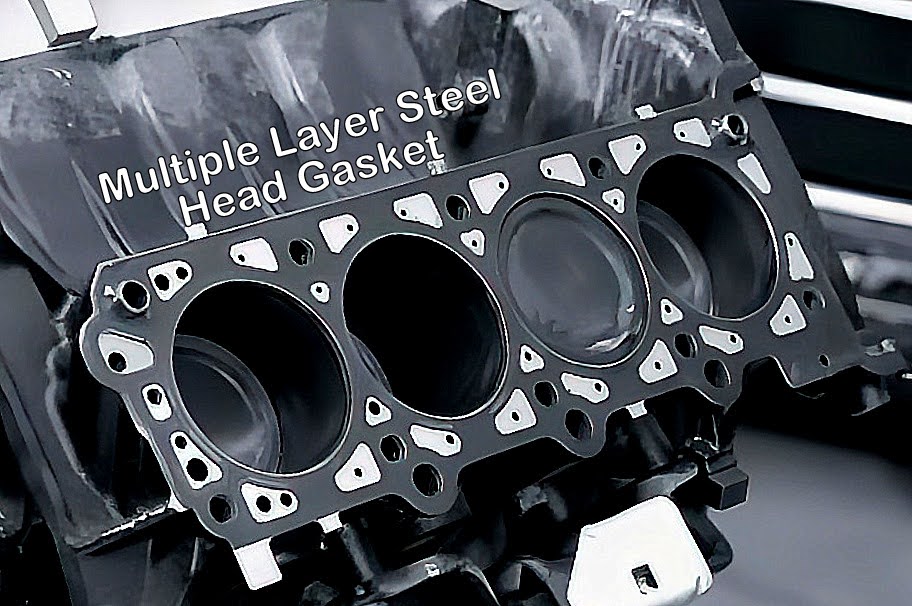

- Gasket set and single-use hardware: head gasket, intake/exhaust gaskets, valve cover gaskets, seals, and torque-to-yield head bolts.

- Fluids and filters: fresh oil/filter and coolant after the repair.

- Machine shop services as needed: pressure-test, crack inspection, resurface, and check valve seats/guides.

- Associated parts if due or contaminated: thermostat, water pump (if timing-belt-driven), timing components, and spark plugs.

Tip: ask your shop to separate “must-have” line items from “recommended while-open” items with mileage-based reasoning. That clarity is the easiest way to trim hundreds without risking a comeback.

What Drives Price by Vehicle and Engine

The core steps are the same—drain fluids, strip accessories, remove timing drive, lift the head, prep surfaces, and reassemble to spec—but packaging and design details change the clock:

- Cylinder count and layout: V-engines and horizontally opposed designs add parts and procedure. A compact inline-four with a timing chain and good access is generally cheaper than a V6 tucked under a cowl.

- Timing architecture: Interference engines with belt service due soon are smart to bundle the belt, idlers, and pump now. You’re already paying the access cost.

- Parts pricing: Some makes keep gasket sets affordable; others require OEM-only components and single-use hardware that add hundreds.

- Model-specific access pain: Tight engine bays or complicated intake/exhaust routing raise labor hours.

Real-world examples from nationwide estimator data show how model and engine skew price. For instance, late-model full-size pickups can run above the national average, while mainstream sedans often sit near the midpoint; individual model pages illustrate those variances (e.g., one popular half-ton truck trim shows a ~$3,200–$4,200 window). Use those ranges to sanity-check any quote you receive.

How much does it cost to replace a head gasket when damage has progressed?

If you caught the failure early, a standard gasket job with minimal machining is feasible. If the engine overheated severely, expect:

- Warped or cracked head: resurfacing or replacement adds machine time and parts.

- Contaminated bearings: coolant in oil can damage bottom-end bearings; your shop should check for glitter in the pan and verify oil pressure.

- Catalyst damage: prolonged burning coolant can poison catalytic converters.

That’s how a mid-$2,000s repair becomes a $5,000+ event. Broader consumer price surveys capture those upper ranges when incidental damage is present, which is why acting quickly matters.

How Shops Actually Price the Job (Step by Step)

- Confirm the diagnosis: chemical block test, compression/leak-down, and looking for combustion gases in the coolant.

- Quote book time for disassembly/reassembly: adjusted for your engine layout and options.

- Add machine shop estimates: pressure test and resurface if out of flatness tolerance.

- Bundle critical consumables: gasket set, new head bolts, coolant, oil/filter, and RTV where specified.

- Layer on recommended items: timing belt/chain components, water pump, thermostat, spark plugs, and hoses if due by mileage/age.

- Final quality steps: torque-to-yield sequences, cooling system bleed, oil flush if contamination was significant, and post-repair road test with verified operating temperature.

Expect 8–12 hours of book time for the mechanical portion on many mainstream engines; some combinations and twin-bank jobs run longer. That time reality underpins most quotes you’ll see.

Vehicle-specific Notes for Head Gasket Replacement

- Subaru flat-fours: Opposed layouts add sealing faces and access considerations; bundling timing components is common and can keep a Subaru Outback owner’s total in check when due by mileage.

- Truck V8s: On popular 5.3-liter GM V8s, manifold and accessory packaging push labor; use the event to address any known lifter/performance concerns if you’re chasing towing reliability. (Estimate bands from national tools reflect that labor premium.)

- Hybrids: A Prius that overheated because of a failed pump or clogged EGR needs careful cooling-system service after the repair; demand a thorough bleed and EGR health check to prevent repeat thermal stress.

- Premium brands: Tight bays and expensive single-use hardware mean a BMW can live toward the higher end of the range even when the basic engine is a four-cylinder.

- Popular SUVs: Packaging in transverse V6s (think midsize family haulers) often adds intake/exhaust complexity you’ll see in the quote.

- Turbo compacts: If you’re eyeing performance from a small turbo two-liter (as in an Evoque-class 2.0 turbo), verify the shop inspects the cooling circuit and intercooler plumbing for contamination during reassembly.

- Mainstream sedans and crossovers: A Honda Accord or Jeep Grand Cherokee with a conventional inline-four is usually near the national average unless overheating was prolonged.

- Work trucks: A Ford F-150 is a good example of where labor time and accessory removal can push totals above a similarly sized sedan; check model-specific estimator pages when price-shopping.

When Replacement Isn’t the Only Decision

If your vehicle’s private-party value is close to the repair quote, compare paths:

- Head gasket only: best when the bottom end is healthy and the head checks straight.

- Used/rebuilt engine: makes sense if coolant/oil cross-contamination ran long or compression is uneven; sometimes cheaper than rebuilding once you add machine hours.

- Move on: if rust, transmission wear, or looming maintenance stacks up, the capital is often better used toward a different vehicle.

Consumer price snapshots that climb into the $5,000–$6,000 bracket typically reflect either extensive collateral damage or premium/labor-intensive platforms—use that context when weighing repair vs. replace.

DIY or Not?

A successful DIY head-gasket job is less about bravery and more about measuring tools, procedure discipline, and workspace. For an experienced enthusiast, some inline-fours are doable; for most owners, professional repair is the more reliable path because:

- Surface prep and flatness checks require precision and cleanliness few home garages sustain.

- Torque-to-yield fasteners demand accurate tools and angle gauges.

- Timing reassembly on interference engines leaves no margin for error.

If you do take it on, assemble this minimum kit:

- Tools: full metric/SAE socket sets, breaker bar, quality torque wrench and angle gauge, straightedge and feeler gauges, gasket scraper, thread chasers, cooling-system vacuum fill tool.

- Supplies: OEM-spec gasket set, new head bolts, shop towels, brake cleaner, RTV where specified, fresh oil/filter and coolant.

- References: factory torque sequences and timing marks for your exact engine code.

Plan for a long weekend and have a machine shop lined up for same-day checks; book time alone often exceeds eight hours, and first-timers will take longer.

How to Keep Your New Head Gasket Alive

- Fix the root cause: Many failures start with a marginal radiator, stuck thermostat, weak pump, or clogged EGR/cooling passages. Reusing those parts invites a repeat.

- Bleed the cooling system properly: Trapped air can spike temps and warp a freshly machined head on the first heat cycle.

- Re-torque? If your engine family calls for a post-heat-cycle check (rare on modern torque-to-yield designs), schedule it.

- Watch the dipstick and level for 1,000 miles: catch tiny leaks before they escalate.

- Don’t ignore early signs: persistent coolant loss, white exhaust on startup, or bubbles in the expansion tank mean stop driving and test. Those classic symptoms correlate strongly with confirmed failures in field data and owner reports.

Used smartly, those tactics keep a costly repair from becoming a second one. And when you compare quotes, anchor your expectations to current national averages and realistic labor times—then decide what to bundle while access is open.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.