Q: Where Is the Crankshaft Sensor Typically Located?

A: The crankshaft sensor is usually located in the timing cover or near the bottom of the block, toward the front of the engine.

Note, however, that the word “usually” is a big one here. The GM 5.3L engine family has the sensor at the rear of the crankshaft, for example, so that the starter has to be removed to access it. Meanwhile, the 4.2L I-6 GM engine in Trailblazers has it on the driver’s side of the engine block at the rear, as does the 2.4L I4 Cobalt.

The GM 5.3L engine family has the sensor at the rear of the crankshaft, for example, so that the starter has to be removed to access it.

– Richard McCuistian, ASE Certified Master Automobile Technician

Some older GM 4 cylinder platforms have the crankshaft sensor right in the center, halfway between the crankshaft pulley and the flywheel. Jeep Cherokees (and some other Jeeps and Dodges) have it in the rear of the engine reading a tone wheel mounted on the flywheel.

The sensor monitors the speed and position of the crankshaft, sending the information to the engine control using an electric signal. It comes in two variants: Hall generators and Inductive sensors. Most crankshaft sensor tone wheels have a tooth every ten degrees with a missing tooth for position information, making the wheel a “36-1” tone wheel.

The crankshaft sensor usually fails due to high heat exposure and wear and tear. It usually causes a no-start when it fails because crank sensor input is used both for ignition as well as for injector pulse timing. So if the crank sensor fails you won’t have either, and the engine won’t start.

Tips on How to Access the Crankshaft Sensor

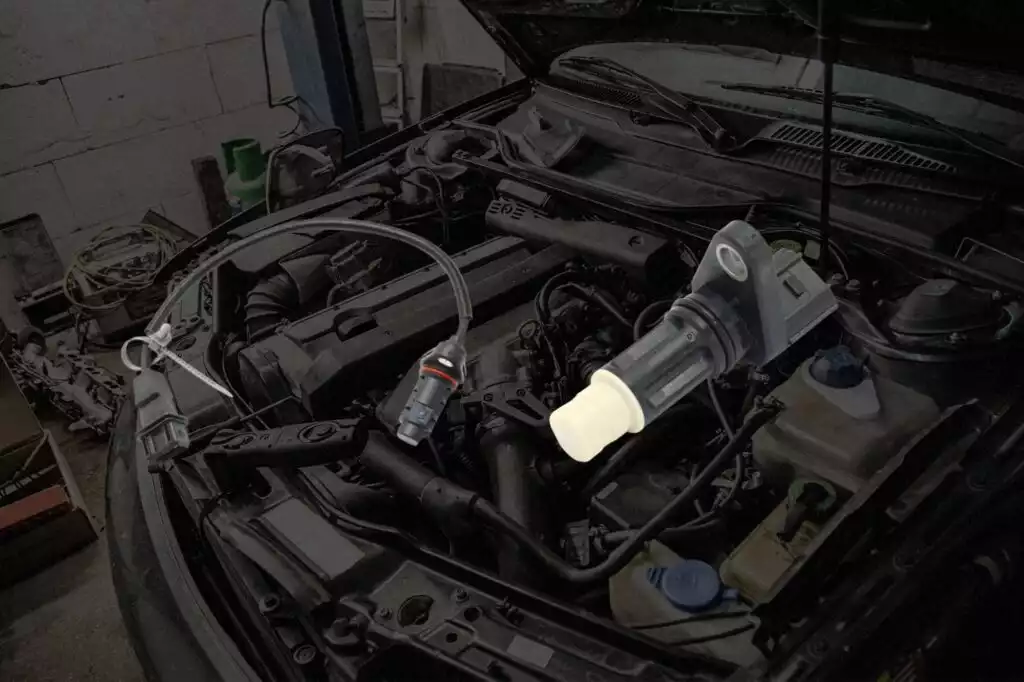

In most cases, accessing the crankshaft sensor doesn’t require any special tools due to its location. All you’ll have to do is check under the hood and look for it. Research what the part looks like in your vehicle so that you have an idea of what to search for.

If you’re planning to replace the sensor, disconnect the battery before starting. Then, release the electrical connector and the sensor mount bolt using a small wrench. Doing so will help prevent a short circuit in the vehicle’s electrical system while you work.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.